Is Polycarbonate a Good Plastic?

Polycarbonate is a versatile, robust, and transparent thermoplastic that has gained substantial attention in numerous applications ranging from eyewear lenses to compact discs. But what exactly makes it stand out among its plastic peers? Is polycarbonate a good plastic for your needs? Let’s delve into its unique properties and applications.

Table of Contents

Understanding Polycarbonate

Polycarbonate (PC) is a high-performance plastic known for its impressive impact resistance and clarity. The fact that it can be moulded easily while still retaining its strength and transparency makes it an attractive choice for many industries.

Key Features of Polycarbonate

- Impact Resistance: One of the primary reasons for polycarbonate’s popularity is its exceptional impact resistance. It’s approximately 250 times stronger than glass and 30 times stronger than acrylic. This resilience makes it an excellent choice for safety glasses, face shields, and other protective gear.

- Transparency: Polycarbonate boasts a clear transparency, similar to glass. This makes it ideal for applications that require clarity, such as eyeglasses or optical lenses.

- Thermal Stability: PC can sustain temperatures of up to 130°C without deforming, allowing it to be used in environments that would be unsuitable for many other plastics.

- Flexibility: It can be easily moulded and thermoformed into various shapes without losing its essential properties.

- UV Resistance: Some grades of polycarbonate come with UV stabilisers, making them resistant to the harmful effects of ultraviolet rays.

Limitations of Polycarbonate

While polycarbonate boasts many impressive features, it’s essential to understand its limitations:

- Scratch Vulnerability: Despite its high impact resistance, polycarbonate can scratch more easily than some other plastics. However, this limitation can be mitigated with hard coatings.

- Chemical Sensitivity: Polycarbonate can degrade when exposed to certain chemicals, so it’s crucial to ensure it doesn’t come into contact with unsuitable substances.

- Cost: PC tends to be more expensive than other standard plastics, which may not make it the first choice for all applications.

Popular Uses of Polycarbonate

Given its unique characteristics, polycarbonate finds itself in a plethora of applications:

- Eyewear: Given its transparency and impact resistance, PC is the material of choice for many spectacle lenses and sunglasses.

- Safety Equipment: Helmets, face shields, and bullet-resistant windows often employ polycarbonate due to its robustness.

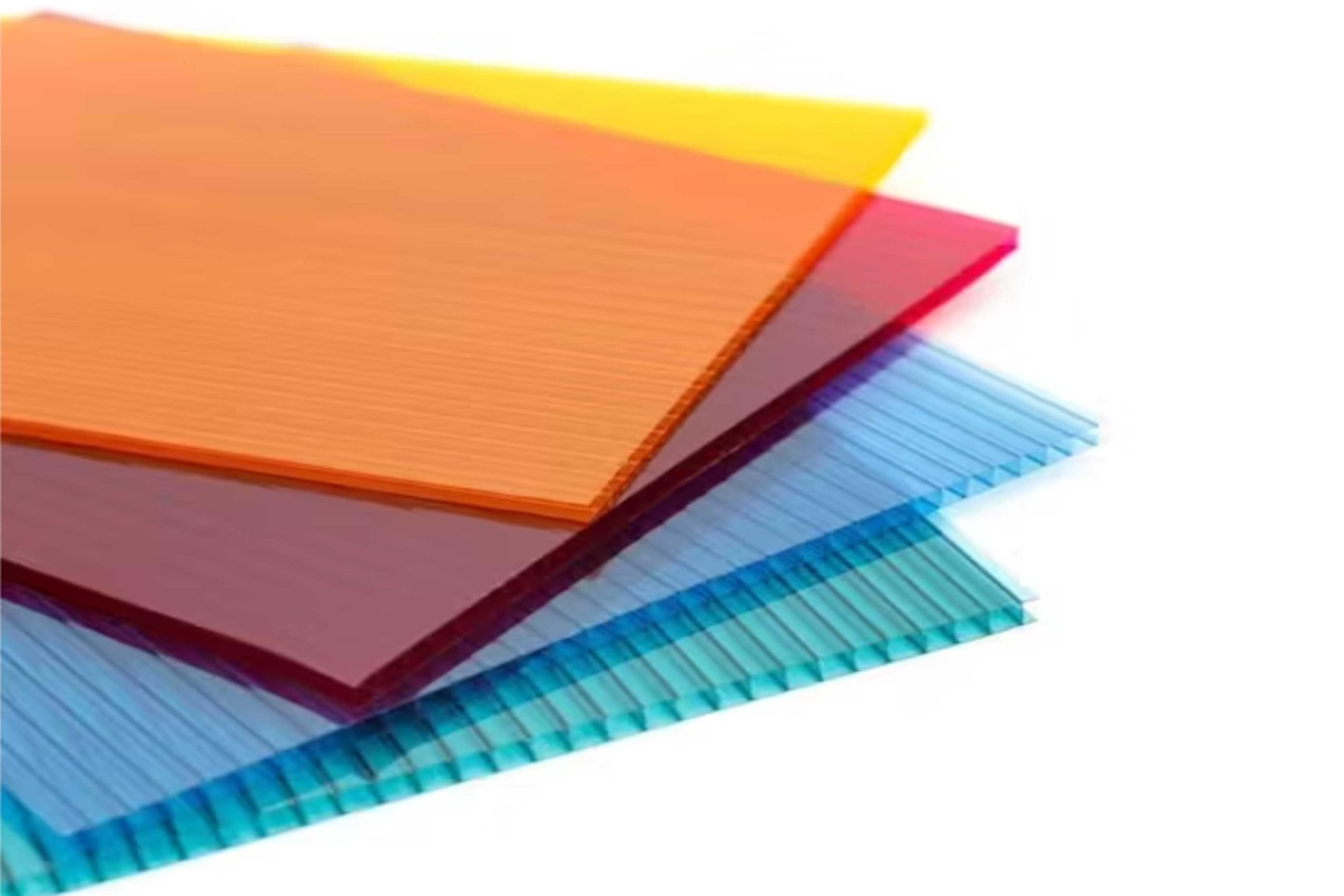

- Greenhouses: Polycarbonate sheet cut to size is often used for greenhouse panels because of its transparency, UV resistance, and insulation properties.

- Medical Devices: Its clarity and strength make polycarbonate a favourite in the medical industry for applications like surgical instruments and connectors.

- Optical Discs: CDs and DVDs are often made of polycarbonate due to its optical clarity.

- Automotive: Polycarbonate finds use in car headlights, sunroofs, and other components, offering weight savings over glass.

The Environmental Impact

With the increasing focus on sustainable and eco-friendly materials, it’s essential to understand polycarbonate’s environmental footprint. While it’s durable and long-lasting, polycarbonate is not biodegradable. However, it is recyclable.

Many industries have made strides to recycle polycarbonate to reduce waste and ensure its reuse in new products. When considering polycarbonate for an application, it’s a good practice to plan for its eventual recycling.

Conclusion

In conclusion, is polycarbonate a good plastic? The answer depends largely on the specific needs of an application. Polycarbonate offers a combination of transparency, strength, and flexibility that few materials can match. Its unique set of properties makes it ideal for numerous applications that demand resilience and clarity.

However, like all materials, it’s not without its limitations. Its vulnerability to scratches and certain chemicals means that it’s not always the best choice for every application. But with an understanding of its strengths and weaknesses, one can make an informed decision on whether polycarbonate is the right plastic for the job.