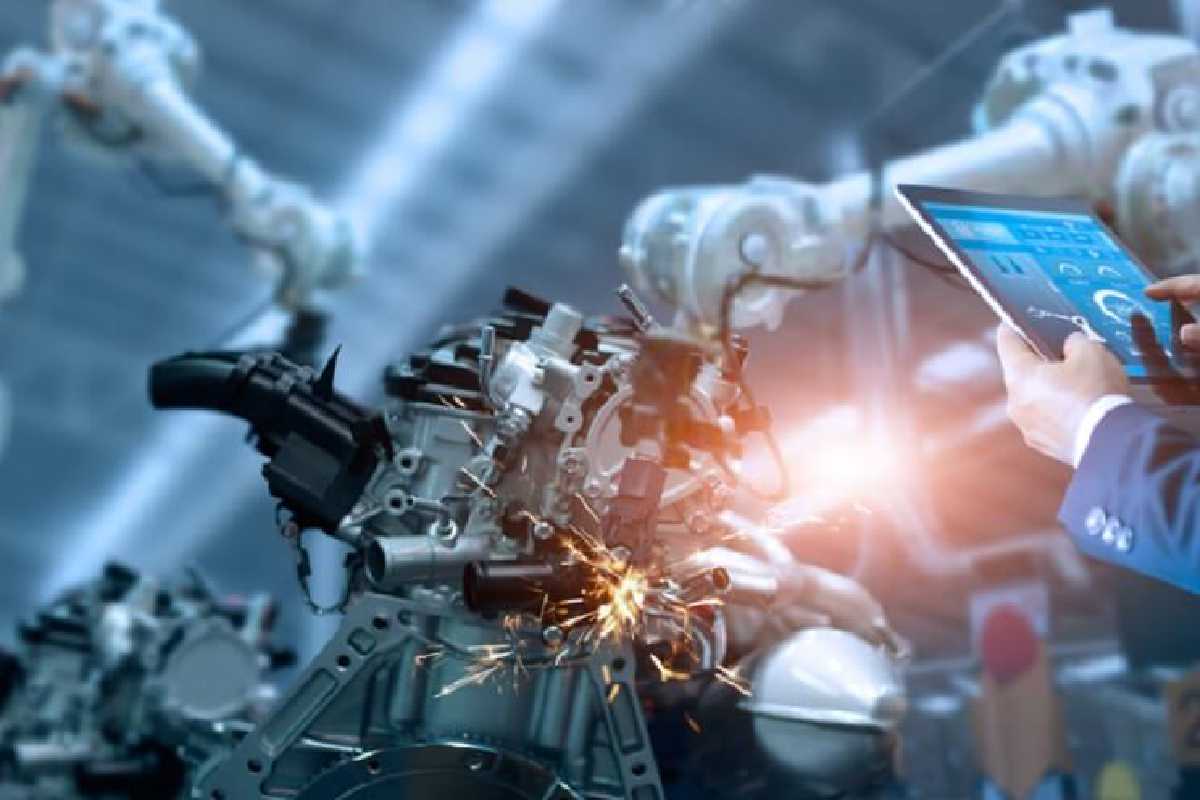

Integrating IT into Manufacturing: Strategies for Optimizing Production and Operations

In today’s rapidly evolving manufacturing sector, standing still is akin to moving backward. As IT managers and business leaders, you’re well aware of the relentless drive for efficiency and innovation in your industry. It’s no longer a question of whether IT solutions should be integrated into manufacturing processes; it’s a matter of how swiftly and effectively this can be accomplished to secure a competitive edge. This article delves into the heart of this challenge, exploring practical strategies for harmonizing IT with manufacturing operations to optimize production. We’re not just talking about keeping pace; we’re discussing transforming the very fabric of manufacturing through intelligent IT integration. So, let’s roll up our sleeves and dive into how you can make this a reality for your company.

Table of Contents

Understanding the Role of IT in Modern Manufacturing

In a world where digital transformation dictates the pace of progress, the role of IT in manufacturing has transcended conventional boundaries. It’s no longer just about supporting operations; it’s about being a pivotal driver of innovation and efficiency.

Why IT Matters Now More Than Ever

Automation and Precision: The advent of technologies such as AI and machine learning has brought unprecedented automation and precision to manufacturing floors. Tasks that were once labor-intensive and prone to human error are now streamlined, leading to enhanced productivity and accuracy.

Real-time Data Analysis: The ability to analyze data in real-time has transformed decision-making processes. IT enables the collection and analysis of vast amounts of data, from machine performance to supply chain logistics, providing insights that were once unimaginable.

Enhanced Connectivity: The Internet of Things (IoT) has interconnected machines and systems, leading to a more cohesive and responsive manufacturing environment. This connectivity ensures smoother operations and facilitates rapid responses to any arising issues.

Case Studies: A Closer Look

Example 1: Consider a car manufacturer that integrated AI-driven quality control systems. The result? A dramatic reduction in defects and a significant improvement in production speed.

Example 2: A textile company implemented IoT solutions to monitor equipment health. This proactive approach to maintenance led to reduced downtime and cost savings.

In essence, integrating IT into manufacturing is not just about keeping up with technology. It’s about reimagining how manufacturing works, making it smarter, more efficient, and future-ready. As we move forward, the fusion of IT and manufacturing will continue to break new ground, ushering in an era of unparalleled productivity and innovation.

Key IT Solutions for Manufacturing

Navigating the landscape of IT solutions can be overwhelming, yet understanding and choosing the right tools is crucial for optimizing your manufacturing operations. Let’s explore some key IT solutions that are revolutionizing the manufacturing industry.

Enterprise Resource Planning (ERP) Systems

- Centralized Control: ERP systems integrate various business processes, providing a centralized platform for managing operations, from procurement to production and distribution.

- Improved Efficiency: By streamlining processes and providing real-time data, ERP systems enhance decision-making and operational efficiency.

Internet of Things (IoT) and Smart Sensors

- Enhanced Monitoring: IoT devices and smart sensors enable real-time monitoring of equipment and processes, leading to proactive maintenance and minimized downtime.

- Data-Driven Insights: These technologies provide valuable data that can be analyzed to optimize production processes and improve product quality.

Artificial Intelligence (AI) and Machine Learning (ML)

- Predictive Analytics: AI and ML can predict maintenance needs and production bottlenecks, allowing for timely intervention and continuous process improvement.

- Quality Control: AI-driven systems enhance quality control by detecting and rectifying defects more efficiently than traditional methods.

Automation and Robotics

- Increased Productivity: Automation of repetitive tasks frees up human resources for more complex tasks, thereby increasing overall productivity.

- Precision and Consistency: Robotics ensure high precision and consistency in tasks that are challenging for human workers.

Cybersecurity Measures

- Data Protection: As manufacturing becomes more connected, protecting sensitive data and intellectual property becomes crucial.

- Risk Management: Implementing robust cybersecurity measures mitigates risks associated with digital operations.

By integrating these IT solutions, manufacturing companies can not only enhance their production efficiency but also stay ahead in a rapidly evolving digital world. The next section will discuss strategies for effectively integrating these technologies into your manufacturing processes.

Conclusion

In the journey towards digital transformation, the integration of IT in manufacturing is not just an option; it’s a necessity for future growth and sustainability. This article has walked you through the pivotal role of IT in modern manufacturing, highlighting key solutions like ERP systems, IoT, AI, and automation that are changing the game in production and operations. We’ve also touched on how these technologies can be seamlessly integrated into your existing processes.

As IT managers and business leaders in the manufacturing sector, you stand at the forefront of this exciting transformation. The integration of IT is a strategic investment that goes beyond mere technology adoption. It’s about fostering a culture of innovation, efficiency, and continuous improvement. The benefits are clear: enhanced productivity, reduced costs, improved product quality, and the ability to make data-driven decisions.